Soybean Field Trial Report

Cultivating 98 Acres

A little over a year ago, Ronald Koptis, successful rancher and farmer, was introduced to agricultural products developed by Gary Champagne of Republic Energy Inc. in Foley, Alabama.

After success in casual experimentation applying these products to ornamental roses, pecan trees and fruit trees Mr. Koptis and Mr. Champagne did a joint field trial growing soybeans with Republic Energy’s soil amendments. For planting Mr. Koptis chose 98 acres in Summerdale, AL, off the dirt County Road 73 between paved County Roads 38 and 36.

This field was selected because, in Mr. Koptis’ words, its soil is “sandy, poor and nematode infested” and, historically, it yielded only 15 to 20 bushels per acre, suggesting we could reasonably attribute any improvement in yield to the ExtraGro soil amendments.

This report outlines the protocol of that field trial and its results.

A New Farming Implement

We applied ExtraGro soil amendments in the furrow at planting in precise amounts. For this application strategy, Ronald and his son Joseph purchased and modified a 6-row KMC Strip Till for 30” with parts from other, used implements to create a novel, proprietary (patents pending) tool. KMC

Planting

Planting took place on June 9th and finished on June 10th. Joseph Koptis recommended 30” double rows with an 8” wide seed bed and 7” spacing on seeds with a bed depth of 14” to 18”. We planted soybeans in all 98 acres per these recommendations with an estimated 170,000 Plants per acre.

Using their modified implement, Mr. Koptis put down powdered, solid “Biocarbon” (solid material produced by Republic Energy) plus phosphate and potash into the opened furrows.

We pulled the implement at a maximum speed of 5 MPH by a 270 HP tractor that was available, although an 180 HP tractor would have been sufficient. A second tractor followed with a spray implement applying a combination of “Liquid Carbon” (Fulvates and Humates produced by Republic Energy) and a proprietary microbial formulation provided by Smart Micro-Bio (SMB) directly into the seed furrows.

We then closed the furrows.

The Koptises intend to modify the implement with hollow trailing tines further to apply Liquid Carbon directly to the furrow and eliminate the need for the second tractor with a sprayer attachment.

This new tool will allow applications of varying amounts of traditional nutrients, Biocarbon and Liquid Carbon, and SMB microbes simultaneously, thereby creating a stable environment for plant root systems to develop in sandy soil and to hold moisture while repelling destructive nematodes.

Biocarbon Application

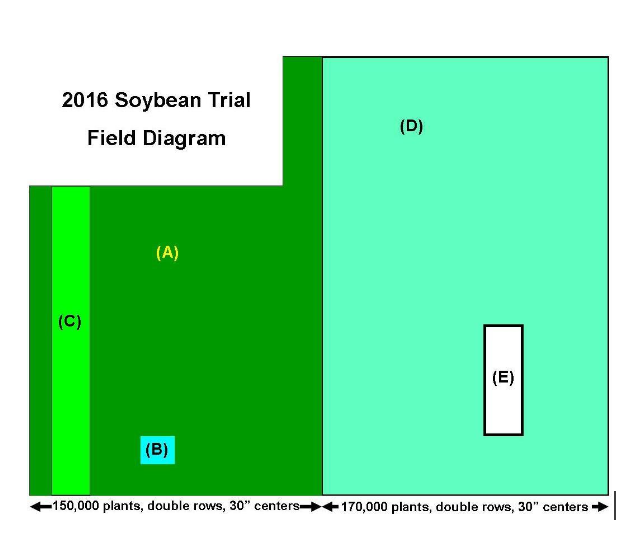

We applied Biocarbon, at a rate of 60 pounds per acre and a half diammonium phosphate and half Potash Fertilizer were in the furrow at 225 pounds per acre with the beans on the 45-acre Section (A), which includes Section (B) (See Field Diagram below).

We excluded the six rows in Section (C) from the Biocarbon application as an additional control.

The same half diammonium phosphate and half potash fertilizer was used on the rest of the acreage, labeled Section (D), at 225 pounds per acre. No Biocarbon was put down on this acreage.

Compared to Sections (D) and (E), where no Biocarbon was applied, there was a noticeably lower plant mortality in Sections (A) and (B), that received the Biocarbon application.

Liquid Carbon Application

We diluted a solution of 12% Liquid Carbon at 30 ounces per 15 gallons of water and added microbes from SMB. We sprayed the solution immediately after planting on all acreage except Section (E) on the Field Diagram below, which consisted of three (3) partial rows approximately 50’ in length.

Microbe Application

250 Gallons of Smart Micro-Bio proprietary microbiology were applied to all 98 acres at one quart per acre in the 15 gallons of water per acre. We applied the microbes at the same time as the Liquid Carbon.

**** There are some exceptions noted on drawing****

Field Diagram

All acreage, except as mentioned below, received two applications of Liquid Carbon and one application of Microbes.

The strength and implementation rates and frequencies of all soil amendments were calculated with caution to avoid damaging the crop.

- (A) – Approximately 45 Acres, 1 Biocarbon, 2 Liquid Carbon & 1 Microbiology*

- (B) – Six 30’ Rows, 1 Biocarbon, 1 Microbiology & 5 Liquid Carbon*

- (C) – 6 Rows, No Biocarbon, 2 Liquid Carbon & 1 Microbiology*

- (D) – 2 Liquid Carbon, No Biocarbon & 1 Microbiology*

- (E) – No Biocarbon, Liquid Carbon or Microbiology. No Healthy Plants or Beans.

Section B

Section (B), (6) Rows by 30’ long, received five (5) additional applications of Liquid Carbon only from a manual back sprayer every three (3) weeks until two weeks before crop maturity.

At maturity, random 21” long row samplings (1/10,000 an acre) were taken in this section, showing 15 plants and 100 beans each (weight per 100 beans = 0.035-0.04 of a lb.).

At 1,500 beans per 1/10,000th acre and 2,800 beans per pound, we calculated the yield in this plot at 89.29 bushels per acre

Note

In hindsight, we used more of each amendment should have because the additional applications in Section (B) indicate that higher utilization rates translate to a higher yield. Planting arrangements would also be changed based on plant mortality and canopy coverage for undergrowth reduction on observations of this poor, nematode infested soil.

.

Control

A small section of 4 rows approximately 50 feet long, labeled “Section (E)” in Field Diagram above, received no Biocarbon, Liquid Carbon or SMB microbiology. This section had no significant plant growth and no yield, which we can attribute to the heavy nematode infestation and the poor quality of the sandy soil.

Growing Period Liquid Carbon Application

All 98 acres received one application over the top of Liquid Carbon, at 40 ounces per acre, combined in 15 gallons of water. The Liquid Carbon replaced half of regular insecticide use and was coupled with a fungicide after we set the canopy.

Harvest

We harvested the soybeans the Week of October 10th.

- It was delayed to let desiccant work for best Combine operation.

- Yield 43.8 bushels per acre. (2.19 times previous returns)

- 2,800 beans per lb. (Normally 3,000-3,500 per lb.)

- No quality deductions.

Observations

- Weather Conditions, i.e. rainfall, were excellent for this 2016 crop

- All acreage that had a least one application of the Republic Energy amendments time staved off Nematodes except Section (E) in the Northeast corner, which received nothing but fertilizer and had a high mortality and had only a few plants with beans. Pictures are available. All areas of the harvest seemed to have the high-quality large beans and many pods.

- Plant mortality in the double rows lowered the overall yield.

- We used a standard application of Roundup through the growing cycle.

- A single application of generic Orthene-type insecticide, at 50% of the average application rate, was made across the entire field immediately after planting costing $9.00 per acre. We used no other insecticide through the growing cycle.

- We applied 50% of the typical application of fungicide across the field at $4.35 per acre.

- Total fertilizer usage was $40.00 per acre.

For Next Year’s Planting

- Planting on 14” single rows with about 140,000 plants per acre.

- 60 lbs. Bio Carbon at planting with Liquid Carbon at 1.5 total gallons per acre utilizing multiple treatments and Microbes as recommended.

- Round Up herbicide, a fungicide, and desiccant if needed.

- Expected results though weather conditions can vary yields

- Anticipated yield based on best results in the 2016 trial Section (B) – 140,000 mature plants per acre X average 70 pods X 2 Beans Average= 19,600,000+ beans per acre /2800 beans per lb. =7,000 lbs. per acre / 60 lbs. per bushel =116 bushels per acre.

Leave A Comment